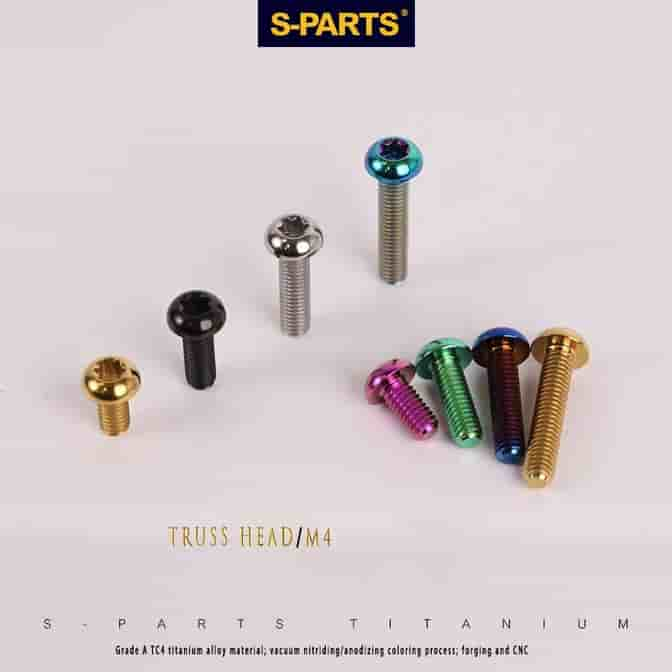

Vacuum nitriding:GOLD/BLUE/BLACK ,all adopt the vacuum ammonia infiltration coloring process, the color penetrates into the metal surface, the color is bright and durable.It will not fade easily with non-strong scratches.

Anodizing: Candy color/green/purple, with anodized coloring process, providing more dreamy options.

This product is made of high-quality A-grade titanium alloy material, which is corrosion-resistant and high-strength. Processing is difficult and expensive. It is mostly used in the aerospace field, or international events such as F1 and motorcycle GP.

Pure titanium: low strength and low price. It is suitable for equipment that does not require strength and only meets anti-corrosion requirements

Recovery/secondary smelting titanium: inferior quality, low price. There is no security.

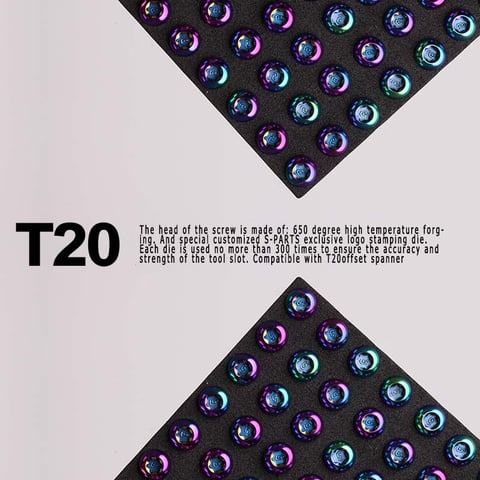

The screw head is forged by "65o degree" high temperature. And specially customized S-PARTS exclusive Logo stamping die. Each mold is used no more than 3oo times to ensure the accuracy and strength of the tool groove. Use a T25 offset spanner

powerful: Strength equivalent to 10.9 grade steel screws

light: Under the same specifications, the weight is about half of that of steel screws, close to that of aluminum screws