Description

- Rustproof: A-grade TC4 titanium alloy material, corrosion-resistant, no rust.

- Level 10.9: Equivalent to 10.9 grade steel screws. (Only for TC4 material titanium alloy products)

- Vacuum nitriding & Anodizing: Using "Vacuum nitriding" or "anodizing" coloring process, the color is gorgeous and not easy to change color

Product material

Power: Strength equivalent to 10.9 grade steel screws

This product is made of high-quality A-grade titanium alloy material, which is corrosion-resistant and high-strength. Processing is difficult and expensive. It is mostly used in the aerospace field, or international events such as F1 and motorcycle GP.

Pure titanium: low strength and low price. It is suitable for equipment that does not require strength and only meets anti-corrosion requirements

Recovery/secondary smelting titanium: inferior quality, low price. There is no security.

Light: Steel Titanium Aluminum Under the same specifications, the weight is about half of that of steel screws, close to that of aluminum screws

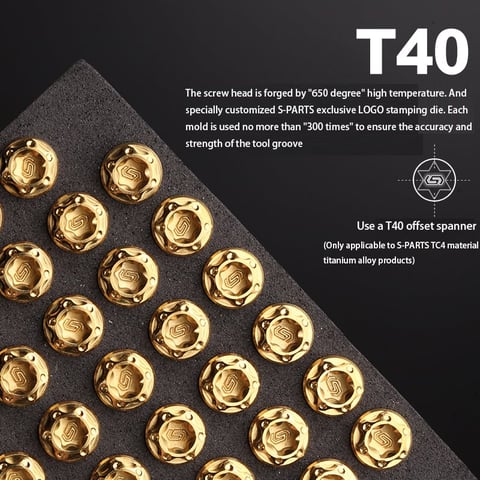

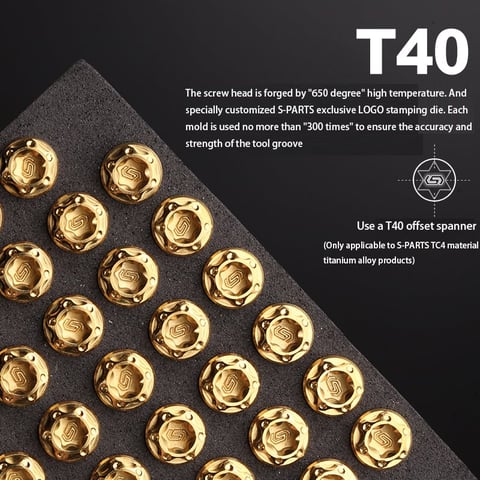

Forging process

The screw head is forged by "650 degree" high temperature. And specially customized S-PARTS exclusive Logo stamping die. Each mold is used no more than 3oo times to ensure the accuracy and strength of the tool groove

Coloring process

Adopt the vacuum ammonia infiltration coloring process, the color penetrates into the metal surface, the color is bright and durable.It will not fade easily with non-strong scratches.

About chromatic aberration

*All products are taken in kind and try our best to show the color you see when you actually receive the goods.

*Due to the difference in light, angle, or screen, there may be chromatic aberration. Please refer to the actual product.

*"Colorful" and "Blue" products, due to the coloring process, the color of each product is not uniform and distributed.